Polymer & Resin - PVC Resin

Polyvinyl chloride (PVC) is a major thermoplastic material finding use in a very wide variety of applications and products. The scientists who developed vinyl in the 1920s had no idea that their invention would come to play a vital role in people everyday lives - helping make products that are safer, easier to use, clearer, cleaner, more durable, more economical and simply better. Today, vinyl is the second largest volume plastic produced in the world.Polyvinyl Chloride is used in two forms; rigid or PVCu, and plasticized or flexible PVC. It is found in applications from thin films though to complex molded parts to rigid pipe.

Vinyl chloride (VCM), the monomer from which PVC is made, was first synthesized in the laboratory of Justus von Liebig in 1835. PVC itself was synthesized by Baumann in 1872. It was not until the late 1920s that the first commercial production of PVC took place in the USA.

Polyvinyl chloride, now commonly known as PVC, is a member of the ethylene family of polymers. The chemical process for making such polymers involves taking the simplest unit, called the monomer, and linking these monomer molecules together in the polymerization process. Long molecular chains are formed called polymers.

The essential raw materials for PVC are derived from salt and oil. The electrolysis of salt water produces chlorine, which is combined with ethylene, obtained from oil, to form vinyl chloride monomer (VCM). Molecules of VCM are polymerized to form PVC resin, to which appropriate additives are incorporated to make a customized PVC compound.

GRADES AVAILABLE

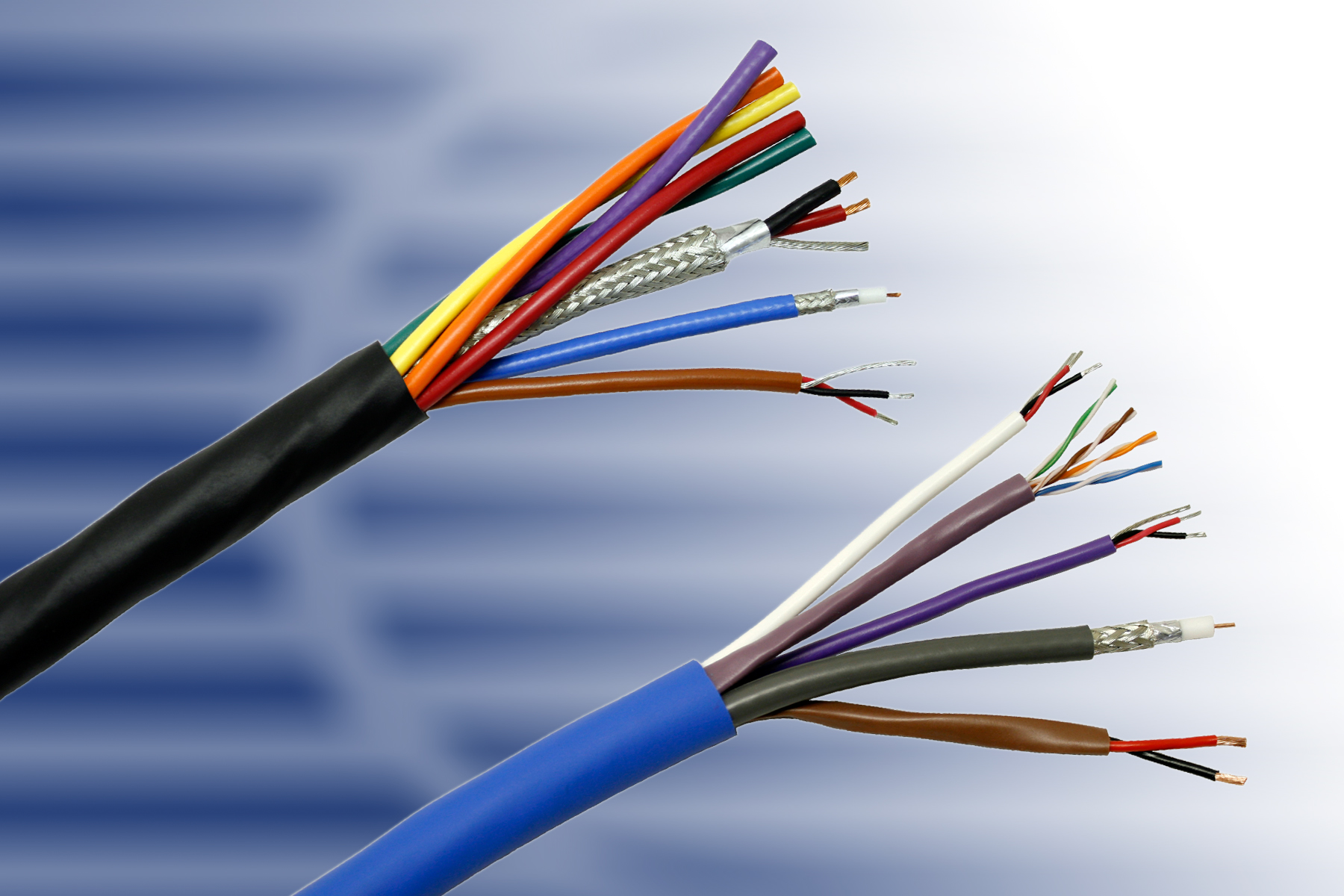

A wide variety of grades of PVC are available, suitable for:

- Blow moulding

- Calendaring

- Cast or blown film

- Coating

- Extrusion

- Injection moulding

- Rotational moulding

- Thermoforming

PHYSICAL PROPERTIES

| Tensile Strength | 2.60 | N/mm |

| Notched Impact Strength | 2.0 - 4.5 | Kj/m |

| Thermal Coefficient of expansion | 80 | x 10-6 |

| Max Cont Use Temp | 60 | oC |

| Density | 1.38 | g/cm3 |